|

|

|

|

Capacitive Sensing, the Hard Way

Part 2 - Building a Touch Panel

Building a capacitive touch-panel from scratch is not an easy undertaking. I

heard about embossing from an other non-electronics project and that could be

used to embed some wires. Otherwise, you'd have to vapor-deposit some

conducting film and etch it in the right form. Vapors and etching are nasty

while embossing can be done low-tech at relatively low temperatures and without

too many lethal fumes.Time for some testing. Take:

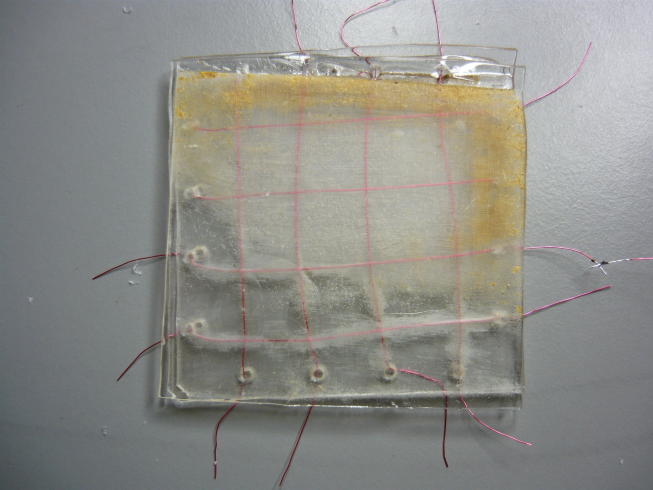

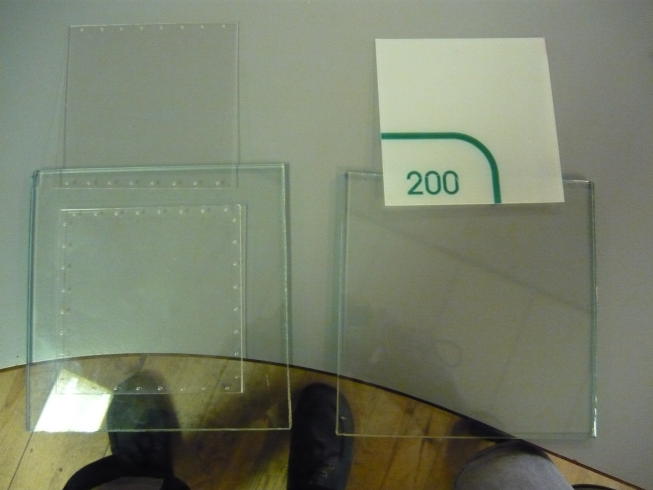

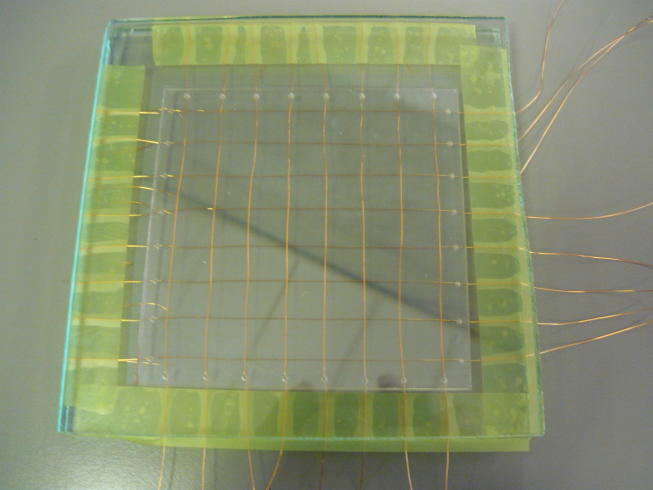

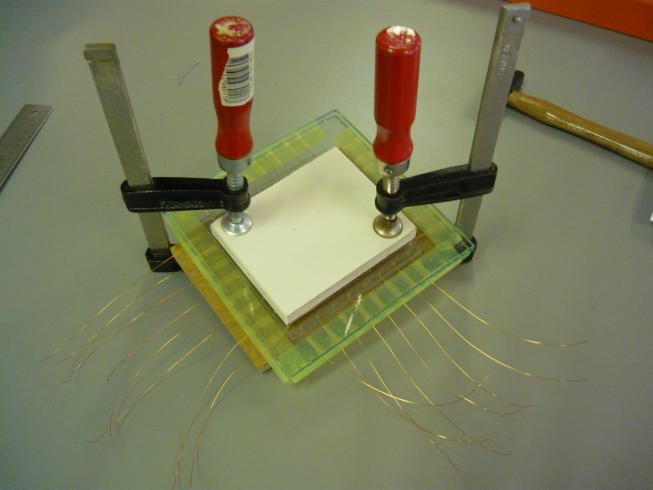

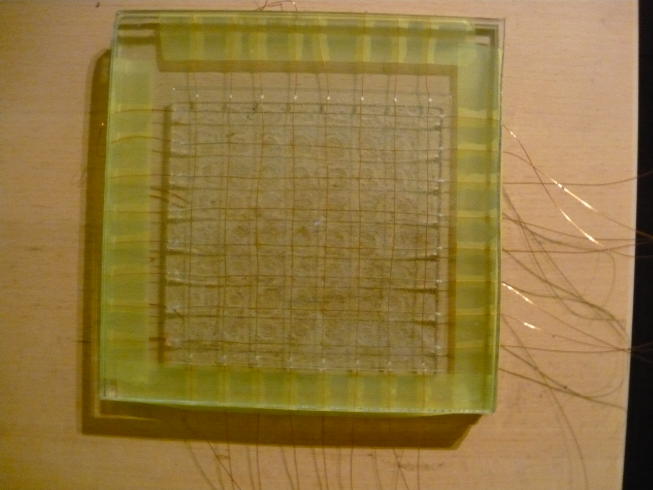

The results were not entirely convincing. The plastic sheets were pressed together with a couple of MDF plates. However, the plastic melts and adheres to the wood like glue. You can't get it off, even if you wanted to. But, the sheets clearly were partly melted and the wires got embedded in the plastic. The final thickness was measured around 2.4mm, so that worked out fine. Time for a new test. What is flat and can withstand high temperatures? Glass. I found some 5mm thick tempered glass plates and that would maybe hold better. Again three sheets of the same plastic with holes (10x10cm in size). This time, the wires are 0.3mm thick.  Mounted with wires through the holes, kept in place under slight strain with tape.  Then put between the glass plates and pressed together between some wooden plates to distribute the pressure.  When cooled down, the plastic has slightly melted and the wires are embedded. Now to get the glass plates off again.  Getting the glass plates off was very difficult indeed. The plastic was glued to the glass. The glass surface chipped off at the edges while trying to remove them and the chips were firmly stuck to the plastic.  I was able to scrape off the chips of glass with a scalpel (careful, using eye-protection).  You can see, on the above image, that the surface is not flat. The problem, as it seems, is that air gets trapped under the glass and it cannot escape. It was noted, after cooling down, that the pressure on the plates was gone. This is because the total thickness is reduced when the wires melt into the sheets. So, any possible squeeze is gone by the time the plastic is partly melted. Anyway, the panel is working, as can be seen in part 1, and that is good news. Next try will involve using steel plates to put pressure on the sheets and a spring-setup to keep the pressure on while in the oven. More to come...

Posted: 2011-09-17 |

| Overengineering @ request | Prutsen & Pielen since 1982 |